The modular inoculation machine is a system capable of processing pour plates and spread plates. The system's modular design means it can be used in any laboratory - large or small. The modular inoculation system can be designed to suit specific needs and also be expanded in the future.

The advantages:

- Reduction in processing time

- High reproducibility

- Major decrease in failures

- Average saving of up to 20%

- Easy to expand as laboratories increase in size

- Easy to implement automation, because manual steps are automated 1 by 1

We consider various models when designing the most suitable machine:

Modular Laboratorial Automation System (MLAS)

De input van deze straat bestaat uit stapels met lege of met medium gevulde

petrischalen. Deze stapels kunnen op het apparaat geplaatst worden in een aanvoerbuffer, met ontstapelaar. Het systeem verzorgt vervolgens de aansturing van de transportbanden en de stapelaar(s) en ontstapelaar(s) zodat de juiste schalen bij de printer worden aangeleverd.

De printer print een label met een unieke barcode en deze wordt op de

petrischaal aangebracht door een applicator. De gegevens voor de barcode, zoals het nummer en eventuele tekst, worden aangeleverd door het LIMS.

Het laatste deel verzorgt de verdeling van de petrischalen nadat de schalen zijn voorzien van een barcodelabel.

De betreffende schalen worden afgeleverd bij de werkplek van de analist die de samples heeft gescanned.

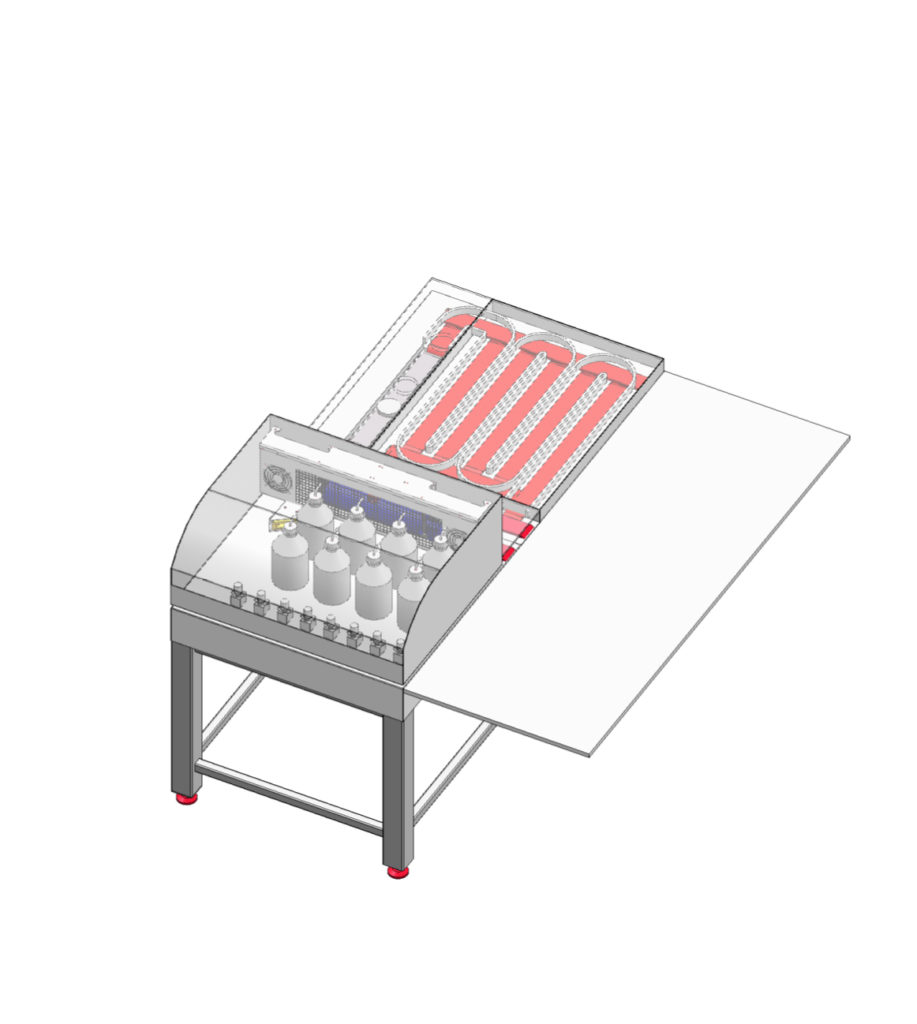

Automated modular inoculation machine - XS

Pouring unit Pouring is the most critical process during inoculation. The pouring unit means that, once bar codes have been scanned, Petri dishes are always issued with the right type of agar (8 types) and the right amount of agar. It is then shaken for 35 seconds, whereby the agar is always coagulated after cooling.

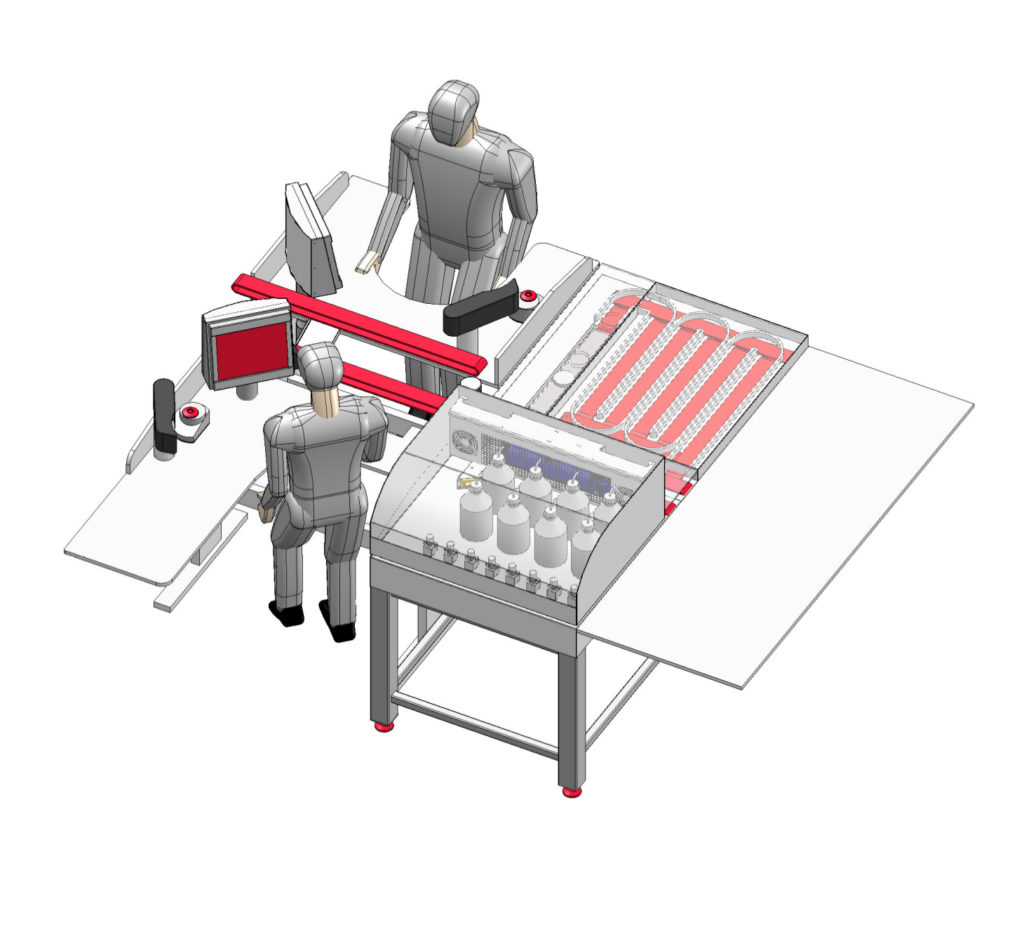

Automated modular inoculation machine - S

Pouring unit – work stations with conveyor belt

The pouring unit is even easier to use if one or two work stations with a conveyor belt are placed before the pouring unit. Once samples have been inoculated, analysts can simply place Petri dishes on the belt, which will take them to the pouring unit. We also place a table after the pouring unit, which can be used to collect the dishes.

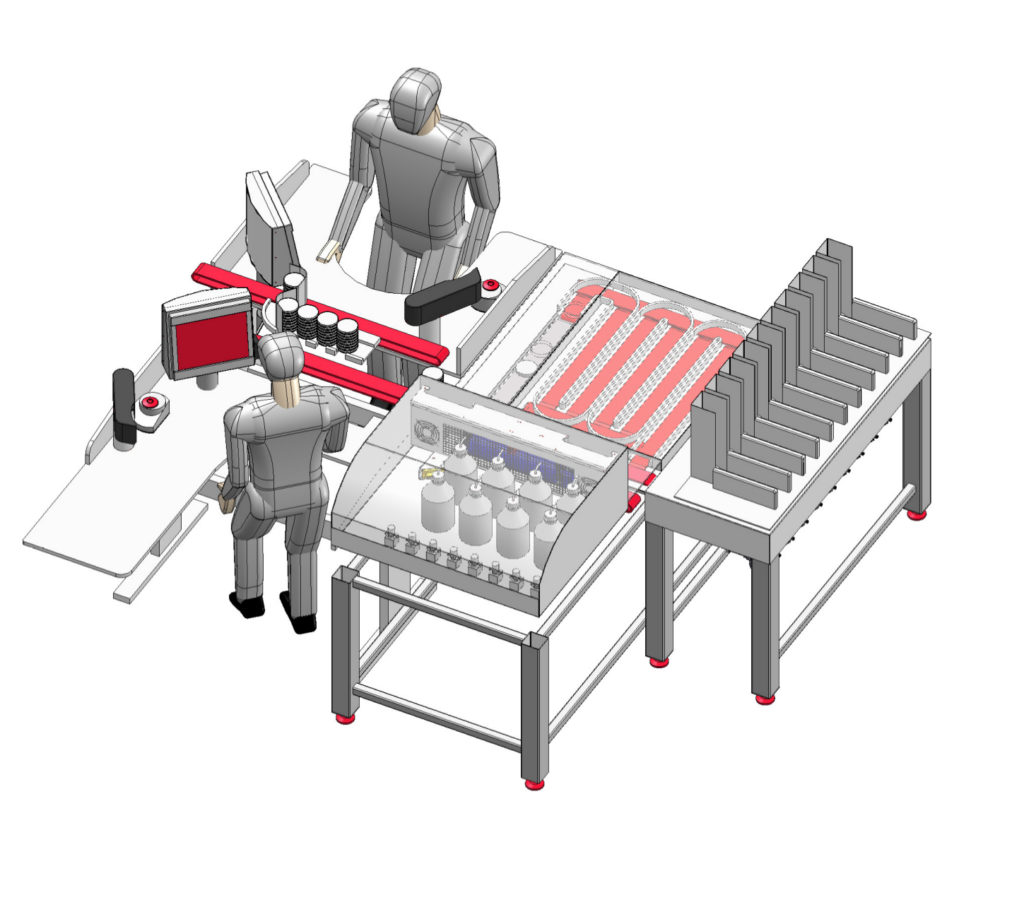

Automated modular inoculation machine - M

Pouring unit – work stations with conveyor belt - stacking unit

A stacking unit can also be used to improve the phase prior to the incubator. The unit sorts the Petri dishes based on agar type or temperature. This means it is not longer necessary to manually search through the dishes!

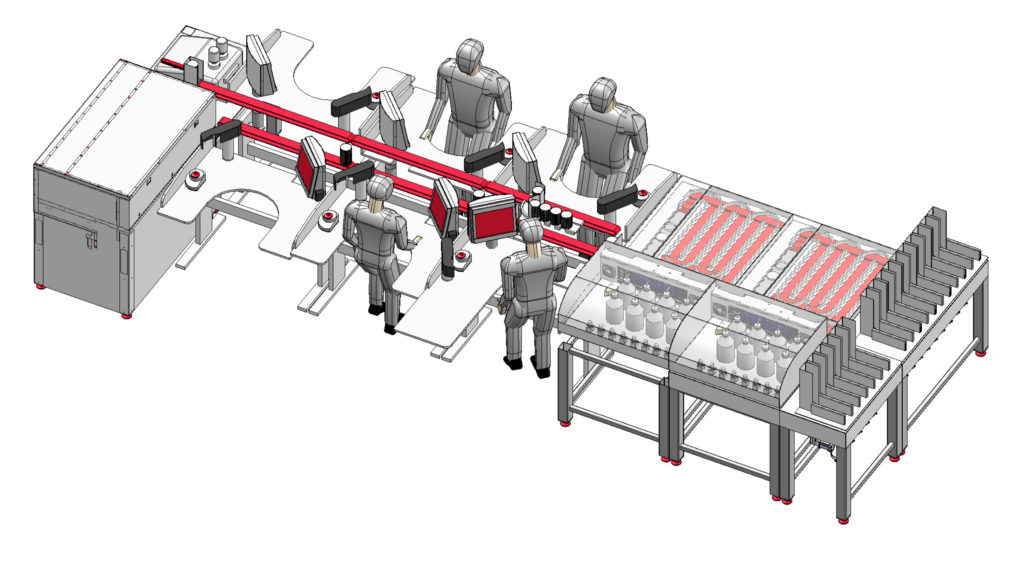

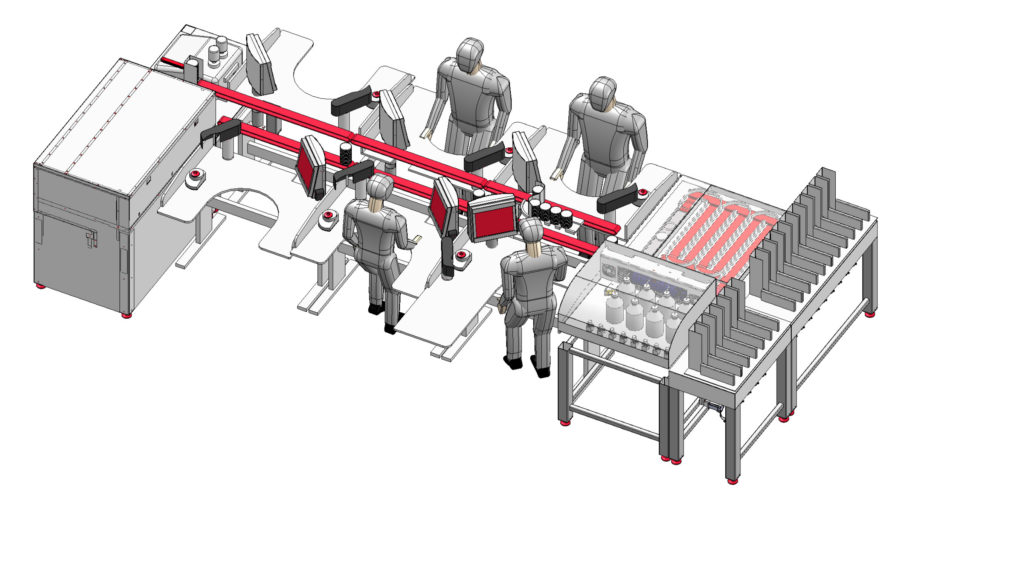

Automated modular inoculation machine - L

Empty/spread plate cartridge – coding unit – work stations with supply and transport – pouring unit – stacking unit

This system uses a LIMS interface to significantly reduce the number of failures. Once the sample has been scanned, the required empty Petri dishes and/or spread plates are automatically sorted, coded and transported to the work station. This means samples will always be accompanied by the right type of dish and never need to be stickered manually. It is possible to opt for two, four or six work stations, whereby two work stations can, for example, be set up to pre-treat samples and thus work in a lean manner. The spread plates pass through the pouring unit via a separate belt and are then placed in the stacking unit for spread plates.

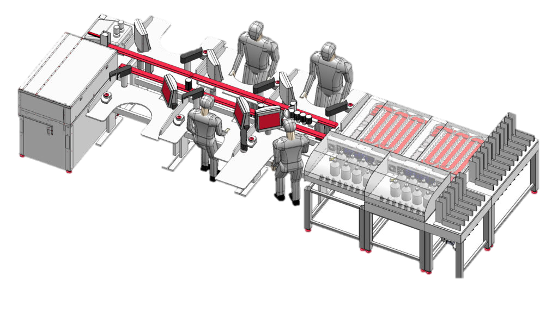

Automated modular inoculation machine - XL

Empty/spread plate cartridge – coding unit – work stations with supply and transport – pouring unit – double pouring unit - stacking unit

Do a lot of Petri dishes need a double poured layer? You can improve the machine's capacity by placing a double pouring unit because double-poured plates no longer have to pass through the pouring unit again. Spread plates are guided around the double pouring unit. dubbelgietunit